IST has the expertise and experience in a wide spectrum of core engineering capabilities across many industries. We stay up to date on the latest technologies so that we can help your company be successful, no matter what your challenge.

Technical Expertise

Learn More About our Technical Expertise

Generally, these solutions encompass a broad range of capabilities consisting of mechanical and electrical design, modeling, a prototype development phase, and deployment.

We are able to assess your requirements quickly and develop an optimal solution for your project.

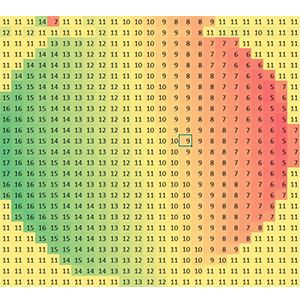

| Sensors and Intelligent Data Regardless of industry, your product may need to capture data, process information, and present options to the user. We not only have experience capturing and processing many types of sensor data, but we design custom sensors for the most challenging applications.

|

|

| Mechanical Design IST Precision offers full mechanical design services utilizing SolidWorks CAD. We provide complete packages including concept design, solid models, detailed design packages with prints, prototyping, and delivery of the final product or process.

|

|

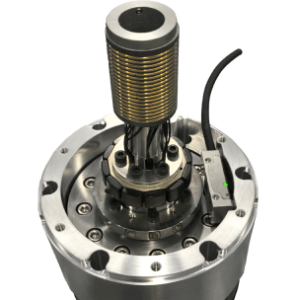

| Opto-Mechanics and Imaging IST provides expertise in opto-mechanical designs and image processing. Through the years we have worked on laser steering applications, vibration designs in optics, optical precision alignment, high-speed image processing, and more. Our experience has included:

|

|

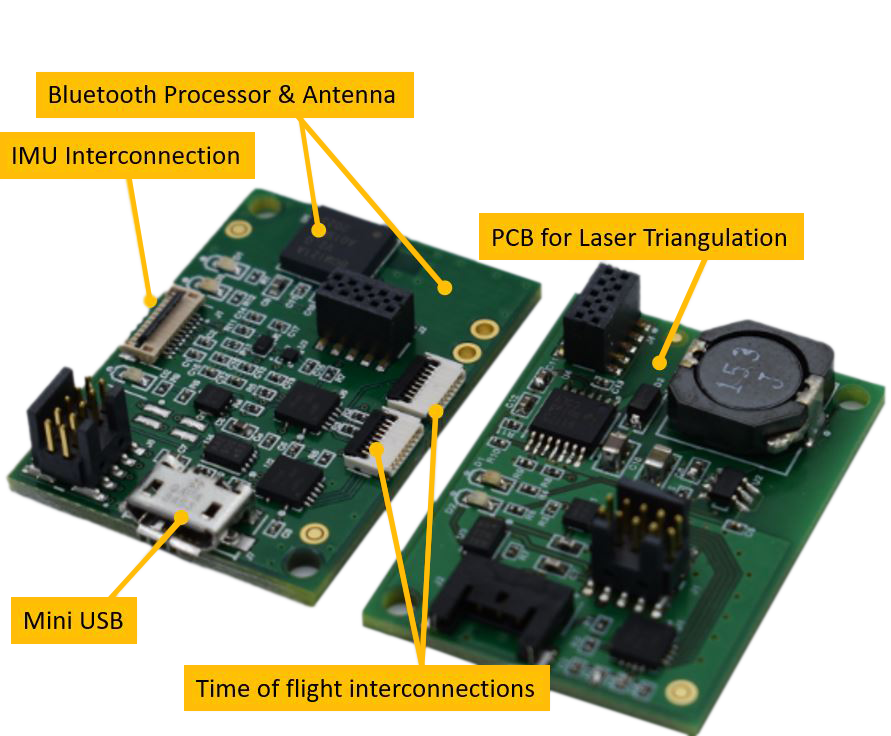

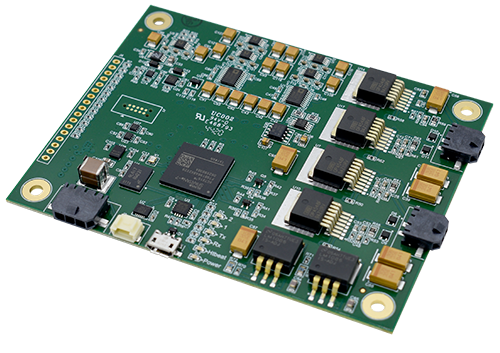

| Our engineers have many years of experience in precision electronic design. We have years of experience in both analog and digital circuit architecture design to enable very precise electrical signals to be generated and detected at a very high accuracy taking into account ground loops, low thermal drift, and optimizing board routing to minimize cross talk. We are equipped to design 1 layer to 15 layer boards, are well versed in ADC and DAC, microprocessors, flash, and many forms of analog design. Examples have included multi-channel phase lock loop circuits, high-speed digital controllers for motion control, and quadrature detectors

Digital and analog PCB Design and Routing

ADC and DAC, Microprocessors, Flash, and Other Forms of Analog Design

FPGA Boards and Firmware

|

|

| Motion Control IST provides programming, ranging from control of simple, single-axis applications to sophisticated, multi-axis coordinated movements, specializing in Beckhoff. Each customer has unique requirements in positioning accuracy, number of axes, control speed, payloads, and off-axis errors. Our knowledge in this area extends across boundaries from the most advanced precision motion to more routine motion such as pneumatic actuators.

|

|

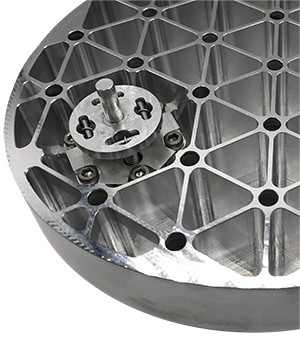

| Manufacturing We have a broad background in manufacturing for nanoscale, microscale, and large scaled parts. Our mechanical engineers have backgrounds as trained machinists which is necessary for optimal engineering design. Many of our designs continually push the boundaries of manufacturing due to challenging specifications and we look to advanced manufacturing practices to enable an excellent part to be realized for prototypes and final design. Some of the processes we use in our designs include chemical etching, wire EDM, high-speed machining, and laser processes. We leverage this background knowledge and our experience as machinists to provide an optimal solution for your project. |

|

| Programming We have expertise in several forms of programming including C, C#, C++, G code, NI graphical code, and VHDL, and also on platforms such as MATLAB, LabVIEW, Xilinx, and Arduino. We have developed code for touch screens, digital filters, demodulation, high-speed controllers, phase-lock loops, high-speed HDMI communication, and high-speed calibration tables, to name a few. Having a solid foundation in both programming, mechanical, and electrical systems, we can accelerate projects quickly and efficiently. |

|

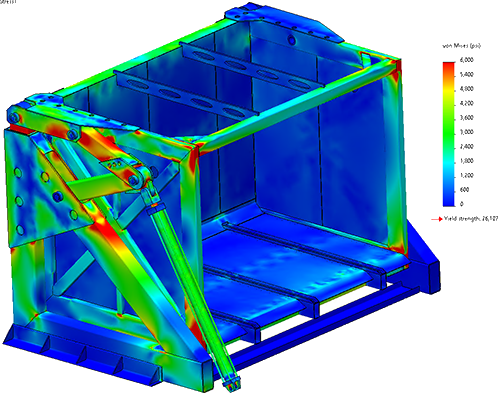

| FEA Simulation We have a full suite of FEA simulation software to enable static, dynamic, thermal, and nonlinear analysis. Our engineers have a solid understanding of first-order principles and use this to compare against our simulations. The simulations have been used to assess resonance modes in structures, develop dynamic absorbers, assess elastic behavior due to cyclical stress loading, model nonlinear elastic behavior due to the interaction of plastic parts, conduct thermal analysis of microheaters, and characterize the dynamic response of systems undergoing base excitations. These tools, combined with our technical backgrounds and expertise, provide a high confidence level that our designs will achieve the required performance levels. This ensures projects remain within deadlines and project budgets are not overrun due to multiple design iterations from unexpected performance levels. |

|